100 years

A short history lesson: Mataró 1920s and the Km0 fashion concept

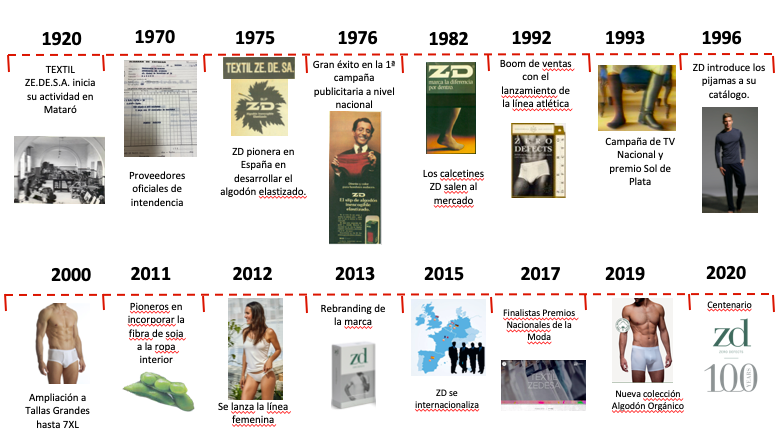

From 1920 up to today, 2020, the busy Santa Marta street, in the heart of Mataró’s downtown has caused ZD’s manufacturing headquarters, in the exact the same spot where it opened its doors at the beginning of the last century. At that time, Mataró was the textile capital of Catalonia.

Back then, a new knitting factory opened every two or three days. Nowadays, however, an artisanal factory-like ZD’s is a rare case in the fashion industry: away from industrial centres and with local workers who often come from families that have worked there for generations.

With strong tights with the community of Mataró, there are several families whose job has been passed down from mothers to daughters.

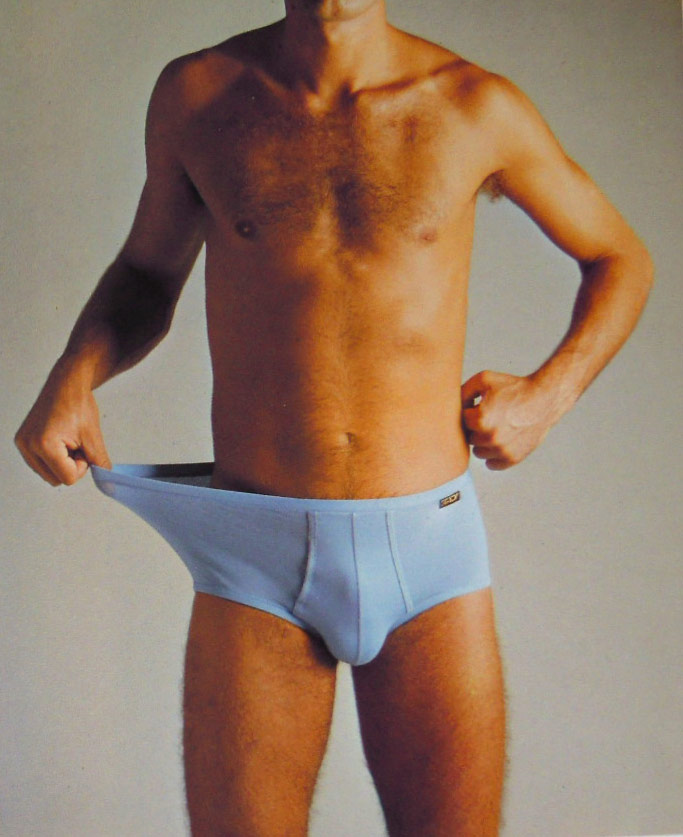

Under the brand name of Caracol, ZD started designing underwear for gentlemen, following the fashion trends of the time. Over time, ZD evolved and expanded, and its current catalogue includes more than 1000 entries and incorporates a large range of sizes and colours.

During the 70s, thanks to a big investment in research and development, ZD experienced a turning point with the arrival of elastic cotton. ZD was a pioneer in Spain implementing this material and created an ambitious marketing campaign nationwide in 1975. The new product was a complete success.

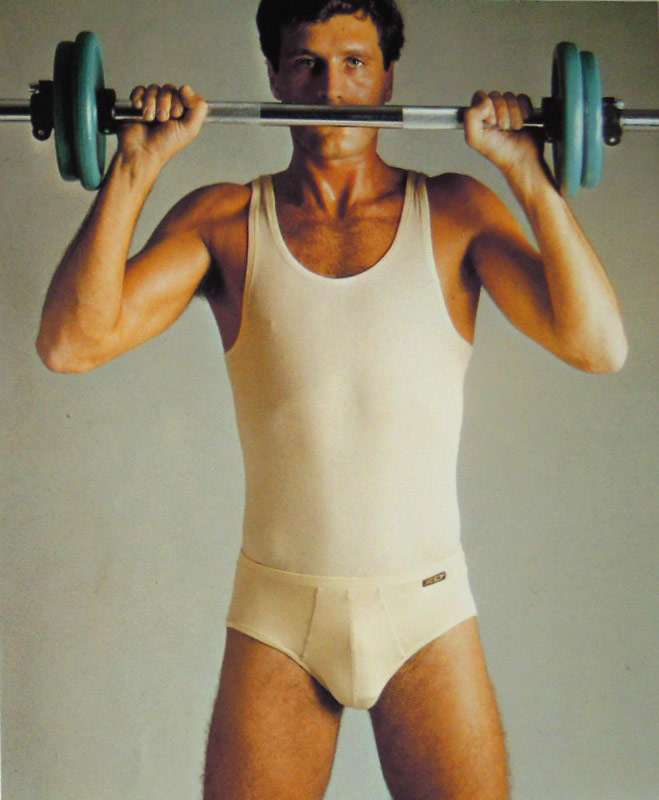

In the 80s, ZD reached its peak with 80 workers and produced 700000 items a year. Back then, ZD also participated nationally and internationally in shows. And in 1992, the new line of athletic garments increased its total gross sales value to a higher level.

2011 brought along a second big revolution for the industry: the use of soya fibre in the creation of undergarments. ZD is the only Spanish manufacturer with soya fibre apparel. The implementation is not more popular because of the extra cost involved, the limited stock available, and the more convoluted production processes that must be implemented. Yet the properties of the resulting garments are exceptional: extremely skin-friendly with antibacterial function, with a silky and soft feel to it, and outstanding moisture absorption and permeability performance, ensuring an extraordinary comfort. Soya fibre is an intelligent, natural, and organic fabric ideal for sensitive or atopy-prone skins and helps prevent allergic reactions.

ZD launched its line of feminine products in 2012. Up to that point, ZD was manufactured exclusively for men, but after seeing firsthand the spectacular properties of the newly developed soya fibre, that were ideal for women’s delicate skins, ZD diversified its product line and introduced undergarments for women.

Even though many small and mid-size textile companies have disappeared or have been taken over by larger international conglomerates, ZD has remained an independent and self-contained brand, standing by its original principles, intent and values: manufacture the best underwear with no shortcuts to reduce costs or quality. ZD constantly invests in the final product through extensive R&D.

In 2015, ZD opened up towards a more international market. Praised by its trajectory and artisan tradition, Europe welcomed ZD’s undergarments’ quality and finishing touches.

In 2015, ZD opened up towards a more international market. Praised by its trajectory and artisan tradition, Europe welcomed ZD’s undergarments’ quality and finishing touches.

After a century of accumulated knowledge and looking towards the future, ZD’s R&D department relentlessly investigates new materials and possibilities to meet today's and tomorrow’s standards and demands.

ZD’s briefs have been number-one surgeons recommended underwear of choice for urology post-op because of the correct amount of support and pressure prevents damaging the surgical suture.

ZD’s briefs have been number-one surgeons recommended underwear of choice for urology post-op because of the correct amount of support and pressure prevents damaging the surgical suture.

Handmade

ZD’s garments are not industrialized or mass-produced; their production falls under the conceptual definition of Slow Fashion. Manufacturing starts with the selection of quality fibres and threads. Moreover, the dying products must be completely natural and eco-friendly. And only exceptionally professional and skilled hands manually cut the pieces.

Because of the delicacy and elasticity of the fibres employed, tailoring these pieces is quite challenging. ZD’s team is highly qualified and has many years of experience, controlling every step of the way (overlocks, coating, seam picks, embroideries, etc.). After the garment is finished, it goes through a last quality check to detect any possible defect. Every ZD garment is handcrafted, marking the difference from mass-produced industrialized products.

Because of the delicacy and elasticity of the fibres employed, tailoring these pieces is quite challenging. ZD’s team is highly qualified and has many years of experience, controlling every step of the way (overlocks, coating, seam picks, embroideries, etc.). After the garment is finished, it goes through a last quality check to detect any possible defect. Every ZD garment is handcrafted, marking the difference from mass-produced industrialized products.

Comfort and demand in every garment

ZD offers a large range of sizes for both men and women. Craft production allows customized tailoring to specific needs and preferences. From the R&D department, ZD investigates and develops new fabrics and designs to obtain pieces that feel and fit like a second skin. This same department verifies the perfection of the final product.

ZD has been eco-friendly for the last century. Regardless of the tendencies in the market, ZD has remained true to the brand’s principles, a positive factor that has contributed to the continuity and strengthening of the company. The values that founded the company have made it excel. The quality of the prime materials and the sustainability of all methods employed are core values that have shaped ZD’s success.